Desktop Metal Single Pass Jetting Technology Enables Mass Production of High-Strength, End-Use Parts in 420 Stainless Steel for Applications Across Medical, Defense, Aerospace, and Consumer Products

Desktop Metal (NYSE: DM) today announced the qualification of Grade 420 stainless steel (420 SS) for use on the Production SystemTM platform, which leverages patent pending Single Pass JettingTM (SPJ) technology designed to achieve the fastest build speeds in the metal additive manufacturing industry. Manufacturers can now leverage SPJ technology for the mass production of high-strength, end-use parts in 420 SS for demanding applications in industries such as medical, aerospace, defense, and consumer products.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20211022005241/en/

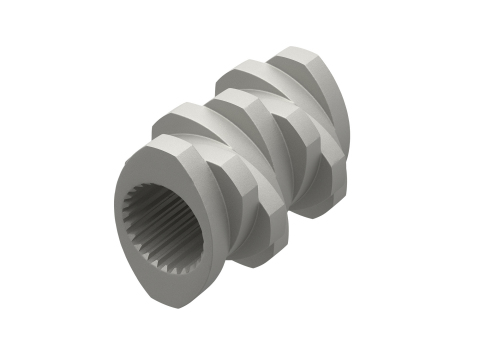

Twin screw extruder mixing elements are used for mixing, compounding and processing viscous materials. 420 SS is an essential material in these applications for its high hardness and corrosion resistance, ensuring the elements have a long lifetime and the hardness required for extruding a wide variety of materials. (Photo: Business Wire)

A martensitic heat-treatable stainless steel, 420 SS is characterized by its high strength and hardness as well as its corrosion resistance to the atmosphere, foods, fresh water, and mild acids when in a fully hardened condition. 420 SS is a common material used extensively across a variety of applications such as surgical and dental instruments, ball bearings, gear shafts, pump and valve components, fasteners, gauges, hand tools, and high-end cutlery.

“Engineers continue to seek out metal additive manufacturing as a leading option to drive innovation in design and manufacturing,” said Jonah Myerberg, CTO and co-founder of Desktop Metal. “We believe our qualification of 420 SS and other high-strength alloys will accelerate the deployment of our AM 2.0 solutions among customers looking to successfully mass produce critical parts at scale.”

420 Stainless Steel - Key Applications

Desktop Metal’s materials science team has qualified and fully characterized 420 SS printed on Production System technology that meets MPIF 35 standards for structural powder metallurgy parts set by the Metal Powder Industries Federation. Parts printed in 420 SS on the Production System platform eliminate the use of tooling and minimize material waste, as well as represent a significant decrease in production time and part cost compared to conventional manufacturing methods.

Examples of key applications include:

- Medical/Surgical - Locking Articulation Bar

Robotic surgical systems used in a variety of medical procedures provide surgeons a better range of motion, enhanced visibility, and a level of precision unachievable with manual surgeries. These systems feature highly precise motion systems with many small intricate parts. The Production System offers high-resolution binder jet printing, making it an ideal solution for achieving the fine features required of robotic surgical instruments. For components like locking articulation bars, 420 SS is a desired material for its high hardness and excellent corrosion resistance. Since no tooling is required to produce these parts with binder jetting on the Production System, volume production can begin as soon as the design is complete, saving valuable time and money on large non-recurring costs of tooling design and fabrication.

- Aerospace - Valve Nozzle Adapter

Valve nozzle adapters connect nozzles with fluid systems in aerospace applications, where multiple versions of these adapters are often required to accommodate various nozzle geometries and sizes. Engineers prefer 420 SS for this type of adapter because of its excellent corrosion resistance and high hardness. With capacity for thousands of adapters in a single build, the Production System can support the manufacturing of these components in 420 SS in volumes competitive with conventional manufacturing methods. In addition, with no tooling required, numerous adapter geometries can be printed within a single build, saving lead time and costs associated with changing over tooling in conventional manufacturing processes.

- High-Volume Manufacturing - Twin Screw Extruder Mixing Elements

Twin screw extruder mixing elements are used for mixing, compounding and processing viscous materials. These parts feature complex lobes around the exterior of the spline that must be optimized for the material being extruded, necessitating a unique mixing element for each different material. With conventional manufacturing, each of these elements can be complex to produce, often requiring advanced machining techniques, multiple machining setups, and custom fixturing. Binder jetting with the Production System simplifies the manufacturing process, enabling large volumes of several, unique mixing elements to be printed in each build, reducing the cost and lead time of production compared to machining. 420 SS is an essential material in these applications for its high hardness and corrosion resistance, ensuring the elements have a long lifetime and the hardness required for extruding a wide variety of materials.

The World’s Fastest Way to 3D Print Metal Parts At-Scale

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System is an industrial manufacturing platform powered by Desktop Metal’s Single Pass JettingTM technology. It is designed to achieve speeds up to 100 times those of legacy powder bed fusion additive manufacturing technologies and enable production quantities of up to millions of parts per year at costs competitive with conventional mass production techniques. The P-50 printer is paving the way for the mass production of end-use parts -- unlocking throughput, repeatability, and competitive part costs. For more information on the P-1, the P-50, and Production System technology, visit www.desktopmetal.com/products/production.

In addition to 420 SS, the Production System materials portfolio today includes nickel alloy IN625, 17-4PH stainless steel, 316L stainless steel, and 4140 low-alloy steel, each of which have been qualified by Desktop Metal. The open-system platform also supports several customer-qualified materials, including silver and gold. The company plans to launch additional qualified metals to its portfolio, including tool steels, stainless steels, superalloys, copper, and more. To learn more about 420 SS and the Production System materials portfolio, visit: www.desktopmetal.com/materials.

About Desktop Metal

Desktop Metal, Inc., based in Burlington, Massachusetts, is accelerating the transformation of manufacturing with an expansive portfolio of 3D printing solutions, from rapid prototyping to mass production. Founded in 2015 by leaders in advanced manufacturing, metallurgy, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make additive manufacturing an essential tool for engineers and manufacturers around the world. Desktop Metal was selected as one of the world’s 30 most promising Technology Pioneers by the World Economic Forum, named to MIT Technology Review’s list of 50 Smartest Companies, and the 2021 winner of Fast Company’s Innovation by Design Award in materials. For more information, visit www.desktopmetal.com.

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, and uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the U.S. Securities and Exchange Commission. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20211022005241/en/

Contacts

Media Relations:

Caroline Legg

carolinelegg@desktopmetal.com

(203) 313-4228

Investor Relations:

Jay Gentzkow

jaygentzkow@desktopmetal.com

(781) 730-2110