Application Compensating capacitor used in intermediate frequency furnace for increase the power of the induction furnace.

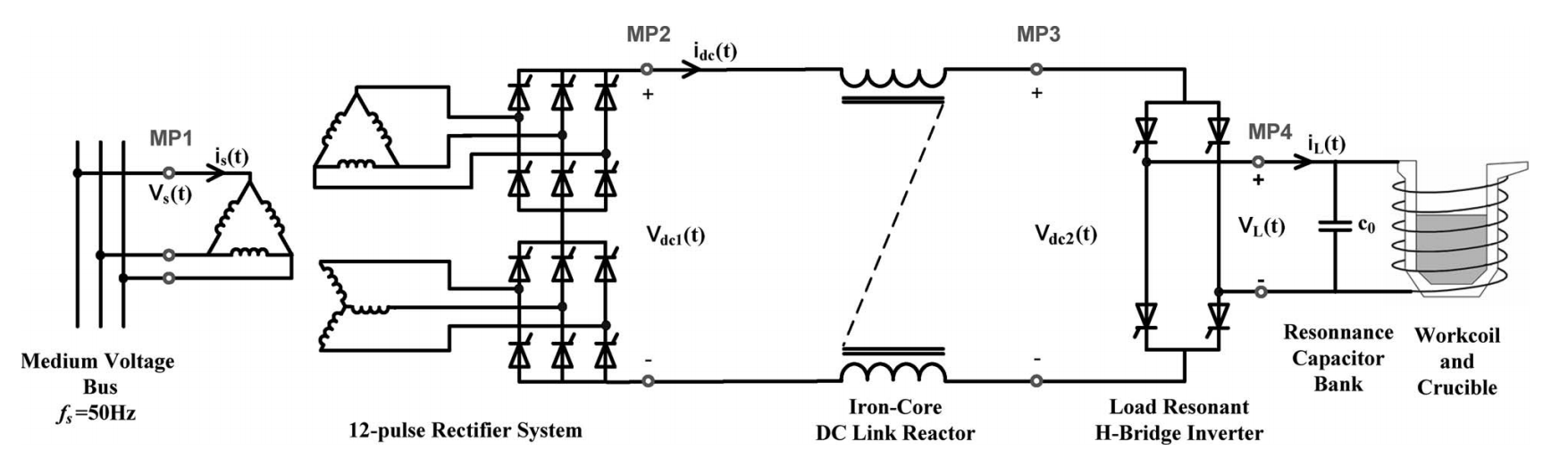

The popular immediate frequency heating/melting furnace generally related to induction coil and resonant capacitors. The fabrication form the induction heating magnetic field. It mainly used for heating, melting, annealing, high-frequency welding etc. The induction heating/melting is well-know method for heating electrically conductive metals. The process convert the power energy into heat energy requires high power efficiency. A parallel capacitors form a resonant circuit employed in the system.

Brief information

In the continuous casting processing for metallurgical manufacturing, compensation capacitors play a big role in the medium frequency induction heating/melting process. The compensation capacitor will compensate the power factor of induction heating power supply and promote the output power, as well as the heating efficiency of the electromagnetic induction equipments.

Products Features

1. The safty protection device (Pressure switch) is available upon request; 2. Power capacitor for intermediate frequency induction heating device usually made-to-order; 3. Internal water cooling design to control capacitor temperature, low-temperature rise; 4. Low dissipation factor, long service life; 5. Impregnated with high insulation biodegradable liquid in vacuum; 6. high-current withstand and high-power design for Electromagnetic induction melting application;

How to solve the huge heat problem of induction melting capacitors?

Since the induction meltinging capacitors are working under high ripple current and high temperature, the huge heating will be generated during the operation. Thus the heat dissipation is of great importance. The induction heating&melting capacitors are mostly designed with cooling water tubes which enhance the capacitor performance, as well as its reliability. The capacitor with good heat disspitation will extend its lifespan, likewise capable of carrying higher power. Furthermore, there are many other cooling methods, like self-cooling, forced ventilation.The simplest way for cooling capacitor is providing enough space around the capacitors. Normally, it is largely insufficient for cooling down the capacitor. In super high power projects, the larger heat load may need additional cooling system, such as an external heat dissipator.

What are resonant functions here in the induction heating/melting power system? 1. Clear off high leakage inductance 2. Adjust the input frequency 3. The formed tuned network could reduce the harmonic content, minimizing the generated electromagnetic interference(EMI).The basic function for induction heating resonant capacitors? 1. Store a significant of reactive power 2. Handle high voltage, high current 3. Low losses for preventing overheating and capacitor failure.

Media Contact

Company Name: Wuxi Flair Electronics Ltd

Email: Send Email

Country: China

Website: https://www.flairelec.com/