Highlights:

Positive National Instrument 43-101 ("NI 43-101") Preliminary Economic Assessment ("PEA") for the BamaStar Mine and Concentrator Plant in Coosa County, AL and a value-add upgrading plant in Mobile, AL. The natural flake graphite concentrate precursor material for the value-add plant will come from South Star's BamaStar and Santa Cruz Mines, which is now in Phase 1 operations in Brazil. First production for BamaStar is planned by 2027.

Pre-tax Net Present Value ("NPV 8% ") of US$2.4B with an Internal Rate of Return ("IRR") of 35% and after-tax NPV 8% US$1.6B with an IRR of 27%.

Life of mine ("LOM") gross revenue of US$9.9B as well as pre-tax and post-tax free cashflow of US$6.0B and US$4.3B, respectively.

19-Year open-pit mine life with an average concentration production of 47,147 tonne per year ("tpy") and a 2.4x increase in Mineral Resource tonnage, which contains over 1Mt of contained graphite.

BamaStar Mine and Concentrator Plant is developed in a modular, phased approach using a simple proven flowsheet resulting in an average recovery of 90% and concentrate grades ranging from 94% graphitic carbon ("Cg") for hard rock mill feed to >98% Cg for oxide mill feed. Each of the planned two phases of the Concentrator Plant would produce approximately 25,000 tpy for a combined total of 50,000 tpy of natural flake graphite concentrate.

The value-add plant is designed using chemical purification technology and standard, commercially available equipment with no intellectual property that can purify to battery grade (> 99.95% Cg). The Mobile, AL Plant is also developed in a phased, modular approach with each of the planned three phases producing 20,600 tpy of upgraded graphite for a total of 61,800 tpy of upgraded products. This amount includes approximately 38,000 tpy of coated, purified, spheronized graphite ("CSPG").

1 Kg of purified graphite was transformed into purified and micronized graphite, as well as CSPG using standard, commercially available, non-proprietary technologies. The CSPG was used to make both CR2032 coin and pouch cells. The successful preliminary electrochemical testing results demonstrated capacity and first-cycle loss performance that is comparable to Tier-1 commercial CSPG products, including potential fast-charge capabilities with stable cycling.

The PEA results have been delivered to the US Department of Defense Title III program managers for review and comment in anticipation of the previously announced grant for funding US$3.2M for the upcoming feasibility study ("FS"). The schedule is to complete the FS within 18 months after the start of drilling program to support the study.

VANCOUVER, BC / ACCESSWIRE / October 10, 2024 / SOUTH STAR BATTERY METALS CORP. (" South Star " or the " Company ") (TSXV: STS )(OTCQB: STSBF ) is pleased to announce the positive results and outstanding economics as presented in the NI 43-101 PEA 1 for the BamaStar Graphite Project ("BamaStar") in Alabama ("AL") USA. South Star is developing a vertically integrated USA battery anode material strategy to supply the expanding worldwide lithium-ion battery ("LiB"), fuel cell, defense and industrial graphite markets.

The BamaStar Project will consist of a graphite mine and concentrate processing facility in Coosa County, AL, as well as a value-add plant proposed in Mobile, AL for upgrading and transforming the graphite concentrates precursor. The proposed value-add plant is strategically located near the port and intermodal logistics facilities, and it will receive natural flake graphite ("NFG") concentrates from both BamaStar and South Star's flagship Santa Cruz Graphite Mine ("Santa Cruz") in northeastern Brazil's Bahia state, which is currently commissioned and ramping-up into commercial production. Santa Cruz is the first new graphite operation to go into production in the Americas this century.

Richard Pearce, President and CEO of South Star , commented: " We are pleased to announce these exciting positive PEA results and encouraging economics for BamaStar. The results indicate the potential for a vertically integrated solution in the near-term for graphite concentrates and value-add production in the contiguous United States in the very heart of the southeast defense, aerospace and electric vehicle corridor where the material is urgently needed. South Star has scalable, diversified portfolio of graphite mines and production facilities in Tier 1 jurisdictions to minimize production risk at a crucial moment for the critical metals sectors in the West. Santa Cruz is ramping up Phase 1 operations and is fully licensed to expand production to 50,000 tpy of concentrates. BamaStar is a past producing graphite mine, with a clear path to restarting, that we are pushing hard to deliver concentrates integrated with value-add products by 2027. We believe our phased, modular approach is financeable, permittable, profitable and scalable at a time when the markets require additional materials and are looking for a stronger, more diversified supply chain of critical materials. Both our projects have proven their potential economic viability and their technical suitability for LiBs and other value-add applications essential to defense, energy storage and the energy transition. South Star is proud of its accomplishments at Santa Cruz as the first new graphite producer in the Americas since 1996. Our team is executing the Company's strategic plan of bringing vertically integrated, phased, modular production in the Americas of midstream and downstream products in a disciplined, technically viable and profitable business plan with a go-to market commercial strategy ."

Mineral Resource Estimate Update

The updated Mineral Resource estimate resulted in an increase to 52.2Mt from 22Mt of Inferred pit-constrained Mineral Resources from the previous maiden Mineral Resource estimate and includes a significant new deeper fresh rock zone that was previously undiscovered. The deposit is open at depth as well as along strike.

Table 1: BamaStar Graphite Deposit Mineral Resource Estimate - Effective Date: July 24, 2024

Type |

Redox State |

Cut-off (Cg %) |

Category |

Tonnes (Mt) |

Cg % |

Contained Cg (Mt) |

Open Pit |

Oxide |

0.90 |

Inferred |

15.1 |

2.24 |

0.338 |

Transition |

0.90 |

Inferred |

8.3 |

2.16 |

0.179 |

|

Fresh |

1.37 |

Inferred |

28.8 |

1.96 |

0.564 |

|

Combined |

0.90 / 0.90 / 1.37 |

Inferred |

52.2 |

2.07 |

1.08 |

Mineral Resource Estimate Notes :

1. Mineral resources were prepared in accordance with the CIM Definition Standards for Mineral Resources and Mineral Reserves (MRMR) (2014) and CIM MRMR Best Practice Guidelines (2019).

2. Graphitic carbon (Cg %) grade was estimated from 1.5 m downhole assay composites using Inverse Distance Squared. No grade capping was applied. Model block size is 15 m (x) by 15 m (y) by 5 m (z). Block volume was assigned on a partial percentage basis.

3. A redox state geological model was developed from verified drill hole and trenching data and used to estimate oxide, transition, and fresh material in the block model.

4. A weathering intensity geological model was developed from verified drill hole and trenching data and used to estimate weathering intensity as strong, moderate, weak, and unweathered in the block model.

5. Bulk density was applied based on weathering intensity and reflects average bulk density determinations of 2.52 g/cm3, 2.57 g/cm3, 2.73 g/cm3, and 2.81 g/cm3 for strong, moderate, weak, and unweathered respectively. The average bulk density for the Mineral Resource is 2.72 g/cm3.

6. Open Pit Mineral Resources are defined within an optimized pit shell with a pit slope angle of 46⁰ and includes a 100 m offset from the highway for mining and 500 m offsets from the highway for oxide and transition-fresh zones respectively where blasting may be required. The pit has an overall 1:1.5 strip ratio (waste: mineralized material).

7. All prices are in US$ currency.

8.Graphite product pricing parameters used in pit optimization include: $980/t bulk concentrate (94.4% to 98.4% total carbon), $3,500/t purified flake/99.95% (micronized, 8 um), $9,500/t CSPG (18 um), and $11,500/t CSPG (8 um). Revenue assumptions are based on assumed sales of 3% bulk concentrate, 19% purified flake (micronized, 8 um), 63% CSPG (18 um), and 15% CSPG (8 um).

9. Costs used in pit optimization vary based on redox state and location and include: waste mining at $2.23/t to $3.10/t moved plus an incremental mining cost of $0.06/t to $0.07/t below the base elevation (250 or 270 masl) and $2.20/t to $3.25/t for mineralized material processing plus an incremental mining costs of $0.03/t to $0.07/t below the base elevation (250 or 270 masl). The processing cost varied by redox state with processing at $11/t to $18.15/t processed, and G&A at $1.74/t processed.

10.Combined graphite recoveries (mill feed to final product) of 84.98% oxide, 84.98% transition, and 86.10% fresh material were applied. Upgrading of the bulk concentrate to finished products used a 94% recovery.

11. Open Pit Mineral Resources are reported at a cut-off grade of 0.90 % Cg for oxide and transition material and 1.37 % Cg for fresh material within the optimized pit shell. The cut-off grade reflects the marginal cut-off grade to define reasonable prospects for eventual economic extraction by open pit mining methods.

12.Mineral Resources may be materially affected by environmental, permitting, legal, title, taxation, sociopolitical, marketing, or other relevant issues.

13.Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. Mineral Resource tonnages are rounded to the nearest 100,000.

Strategic Production Plan

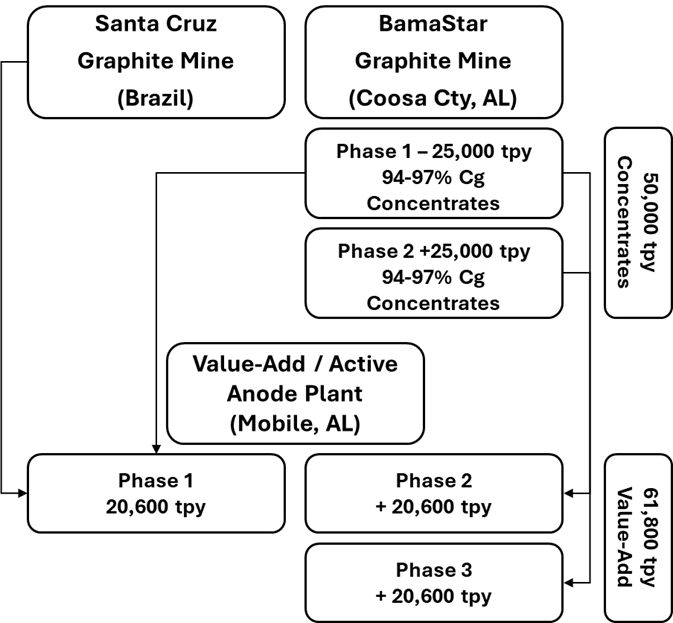

The strategic plan for the Company is to have two mines producing a total of approximately 100,000 tpy of high-quality NFG concentrates and a value-add plant in Mobile, AL producing a total of approximately 61,800 tpy of high-value, upgraded, transformed graphite products, including 38,000 tpy of CSPG. The production plan is presented in Figure 1 below.

Figure 1: Phased, Modular Strategic Production Plan

Mine and Concentrator (Coosa County, AL)

Past Producer: The BamaStar Project is located within the Alabama Graphite Belt ("AGB") and covers the historical Ceylon Graphite Mine. The AGB is a 112 km (70 miles) long, northeast-trending belt in the Clay, Coosa and Chilton counties in Alabama. By 1906, there were several mines in operation and by 1913, the graphite industry was well established in central Alabama. The end of World War I and the resumption of foreign imports depressed prices and the Alabama graphite industry dwindled to seven operating plants in 1920. In 1929, the Ceylon Graphite Company in Coosa County was shut down.

Open Pit Mining with At-Surface Mineralization: Open pit mining is the proposed mining method with the initial 6 years focused on oxide material. As time passes, the mining will extend into transition and fresh rock materials. The mine schedule consists of 42.3 Mt of mill feed grading 2.11% Cg (diluted) over a processing life of 19 years. Open pit waste tonnage totals 66.5 Mt and will be placed into various waste storage areas together with filtered tailings. The overall open pit strip ratio is 1.6:1 of waste: mill feed. The mine schedule utilizes open pit mining areas to supply mill feed up to a maximum of 1.3 Mtpy for Phase 1 and 2.6 Mtpy for Phase 2 to the mill facility.

Excellent Existing Infrastructure in Mining District: The BamaStar Concentrator Plant is located near the open pit mine and US HWY 280. To reduce initial capital cost and operating cost estimates, the phased, modular plant is designed to produce 25,000 tpy of NFG concentrate processing oxide material during Phase 1 and an additional 25,000 tpy in Phase 2 processing the more compact material. Phase 2 has a similar design flowsheet to Phase 1, but with additional grind capacity to process the more compact materials coming from the mine.

Simple, Proven Flowsheet with Excellent Recoveries : A metallurgical process development culminated in a flowsheet producing an average recovery of 90% and concentrate grades ranging from 94% graphitic carbon ("Cg") for hard rock mill feed to >98% Cg for oxide mill feed. The BamaStar Mine and Concentrator Plant was developed in a modular, phased approach using a simple flowsheet with established and proven mineral processing technologies.

The run-of-mine ("ROM") material will be transported to the ROM stockpile. A front-end loader will feed the ROM material on a coarse mineral sizer followed by a fine mineral sizer. The crushed fine feed will be ground in a semi-autonomous grinding ("SAG") mill. The SAG mill discharge will be screened on a vibrating screen, and the oversize recycled to the SAG mill. The undersize will be pumped to the cyclones. The SAG mill will operate in closed-circuit with cyclones. The cyclone overflow will gravitate to the rougher flotation, and the underflow will return to the SAG mill. Most of the liberated graphite will be recovered at the rougher stage. The standard flotation reagents used will be diesel oil and methyl isobutyl carbinol ("MIBC"). The rougher concentrate will be upgraded further in six cleaning stages to produce a high-grade graphite concentrate. The rougher concentrate from the first cleaning stage will be processed in a polishing mill using ceramic grinding media to scrub off gangue minerals from the flakes. Similarly, the graphite concentrates from the second and third cleaner flotation will be treated in stirred media mills ("SMM") using ceramic grinding media. The third cleaner concentrate will be upgraded in the fourth, fifth and sixth cleaner flotation stages. The rougher tailings and the cleaner tailings from the first to the fourth cleaner flotation stages will be subjected to solid liquid separation in a tailings thickener. Thickened tailings will be dewatered further in a disc filter to produce filtered tailings and sent to the co-disposal waste storage facility. The filtered tails will allow for approximately 80% of the process water to be recycled.

The final graphite concentrate from the sixth cleaner flotation stage will be dewatered in a filter press followed by a rotary dryer to reduce the moisture content to less than 0.5% w/w. The dried graphite concentrate will be screened to produce +150 µm (+100 mesh) and -150 µm (-100 mesh) products and bagged in a bagging system.

The simplified testwork flowsheet for Phase I plant is presented in Figure 2. The Phase II plant will include a replication of the Phase I flotation circuit plus a ball mill in the comminution circuit.

Figure 2: Phase 1 Simplified Testwork Flowsheet

Figure 3: Phase 2 Simplified Testwork Flowsheet

Value-Add Plant (Mobile, AL)

Dorfner Anzaplan GmbH ("ANZAPLAN"), a firm specializing in testing and designing facilities for converting NFG into value-add products, such as battery anode material, received 4 kg (8.8 lb) of NFG derived from BamaStar and successfully purified 2 kg using Hydrofluoric and Hydrochloric Acid to a Fixed Carbon ("FC") content of ≥99.95% from the NFG concentrate, which had a FC content of 93.47%, thereby confirming the suitability of the graphite from BamaStar for achieving battery-grade anode purity.

Subsequently, 1 kg of the purified NFG was micronized, spheronized and coated with a standard commercial carbon pitch at a US independent laboratory, and the resulting CSPG was transported to a US battery design laboratory for slurry design, as well as coin cell and pouch cell performance testing. The BamaStar CSPG was thoroughly characterized, investigating the active anode material's rheological, mechanical and electrochemical properties for performance testing. All downstream transformational work and associated electrochemical testing were performed by an independent battery laboratory service provider in North America, under the direct supervision of South Star and the technical consultants.

The following outlines the industry-indicative process workflow utilized to transform the purified BamaStar NFG into battery-ready CSPG:

Micronization: sizing of the purified BamaStar NFG was achieved via an industry-standard conventional air-milling process;

Screening: The micronized, purified material was then screened, via industry-standard sieve screening, to achieve the targeted particle sizes for subsequent spheronization (shaping);

Shaping and Classification: The screened material was then fed into a commercial spheronizer, in order to shape the material into potato-shaped ovoids resulting in spheronized graphite ("SPG"). The unspheronized purified graphite was segregated from the SPG resulting in the purified, micronized, graphite byproduct;

Coating: The BamaStar SPG was then pitch (carbon) coated (or "surface treated") to produce the finished, battery-ready CSPG. The thin layer of petroleum based commercially available pitch coating was achieved through the application of soft-carbon precursor, resulting in the curing and polymerization of the exterior coating on the surface of the SPG. This CSPG is the battery-ready anode material suitable for electrochemical performance testing in Li-ion battery cells.

Figure 4: Simplified Mass Balance for Value-Add Plant Module

Phase 1 will process 21,300 tpy NFG from Santa Cruz and BamaStar. Subsequently Phases 2 and 3 will each process 21,300 tpy NFG from BamaStar Mine and Concentrator. All midstream and downstream transformational technologies and processes, including all associated equipment and consumables (including reagents) for the proposed value-add plant are state-of-the-art and well-established industry standards utilized by global leaders in commercial graphite processing and active anode materials manufacturing. South Star is proposing to only incorporate off-the-shelf equipment and technologies that are commercially available, accepted and expected by all major potential battery clients. No new, unproven or proprietary technologies and/or processes are being proposed, nor is there any new IP relating any aspect of the value-add plant as presented in the PEA.

Each phase or module of the value-add plant is designed to produce 12,600 tpy of CSPG, comprising Medium CSPG and Fine CSPG products, with a FC content of ≥99.95%. In addition, the Anode Plant will produce an uncoated SPG fines by-product at 8,000 tpy. The nominal design of the Anode Plant is based on a NFG feed rate of 21,300 tpy per expansion phase, containing an FC content of ≥95.0%. The NFG is purified in the Purification Plant to produce 20,000 tpy of purified NFG with a FC content of ≥99.95%. This is fed to the Spheronization Plant where the NFG is first micronized followed by spheronization. The spheronization consists of two stages to yield 10, 000 tpy of Medium SPG and 2,000 tpy of Fine SPG. The purified spheroidized product is fed to the coating plant, which after adding pitch tar, yields 12,600 tpy of battery-grade, active anode, CSPG product with a FC content of ≥99.95%.

Figure 5: Simplified Process Flowsheet for Value-Add Plant Module

Electrochemical Testing Results

The battery-ready BamaStar CSPG produced at the US Process Lab was delivered to US Battery Labs, an independent laboratory located in the US, which specializes in battery materials characterization, building Li-ion battery cells (both coin and pouch-cell formats) and battery testing to assess battery electrochemical performance. The BamaStar CSPG was subject to rheological studies and electrochemical performance test work in both coin-cell and pouch-cell Li-ion battery formats.

Tested Both Coin and Pouch Cells: The initial characterization of the BamaStar CSPG included the mixing and casting of graphite anode slurries to produce electrodes (specifically, anodes) to commence half-cell testing in order to determine basic material electrochemical performance metrics, e.g., irreversible capacity loss (ICL or first-cycle loss), reversible capacity, resistance, and Coulombic efficiency. Ultimately the purpose of building and testing Li-ion batteries with BamaStar CSPG is to determine the CSPG's initial electrochemical performance, in comparison to a commercial reference material.

Good Rheological Design and Application to Substrata: In terms of rheology, the BamaStar CSPG mixed perfectly in a conventional commercial anode slurry recipe, using industry-standard conductive additives, binders and solvents. The initial electrochemical performance test results of BamaStar CSPG demonstrate capacity and first-cycle loss that meets or exceeds the performance of Tier-1 commercial NFG-based comparable battery-ready CSPG products.

Positive Electrochemical Performance: The BamaStar CSPG performed well as battery anode materials and experienced a first-cycle loss of 7% and an average reversible gravimetric capacity of 361 mAh/g (approaching the theoretical maximum of 372 mAh/g for natural graphite). In pouch-cell testing, the BamaStar CSPG showed significant potential capabilities for fast-charging Li-ion battery applications, with stable cycling up to 3C. These are excellent initial test results, given that this preliminary performance testing program was non-optimized and is currently ongoing.

No Proprietary Equipment/Technology or IP Proposed to be Utilized: No aspect of the BamaStar materials characterization, rheological studies, battery construction and electrochemical performance testing is proprietary or confidential. Further, all technical work conducted on the BamaStar CSPG is indicative of the evaluation and qualification test work that any potential commercial Li-ion battery customer would undertake to assess a CSPG.

Figure 6: Electrochemical Results Coin Cells Charging Data

Figure 7: Electrochemical Results Coin Cells Discharging

Environmental Permitting/Licensing Strategy

South Star has initiated an environmental geochemistry testing program to assess if BamaStar has water quality risks, including a series of static and kinetic tests on waste rock, mineralized materials and tailings. The testing program has determined that the waste rock is potentially acid consuming ("PAC") or non-acid generating ("NAG"), while it also determined that the tailings product is potentially acid generating ("PAG") due to the presence of sulfide minerals (primarily pyrite). However, the acid-consuming potential of the waste rock exceeds the acid-generating potential of the tailings by over three times, and the studies have determined that the best solution to mitigate acid rock drainage ("ARD") and metal leaching ("ML") risk is to co-dispose PAC waste rock with PAG tailings. This "waste blending" mitigation strategy is a widely applied best practice for mitigating geochemical risk.

Similarly, metals leaching potential was also tested on a representative range of rock types encountered at BamaStar as well as on tailings samples. Geochemical tests confirm that the waste rock at site has little metal leaching risk. Mine tailings showed a potential for metal leaching, which requires further study and sampling. Once again, based on the existing data set, it appears that co-disposal is a cost-effective and viable solution to mitigate the risk of metals leaching. Following best-practice, long-duration kinetic testing to determine the ARD and ML risk is ongoing.

The mine and concentrator are on private land and private mining claims. The PEA will be used as the basis for upcoming permitting efforts for both the mine and concentrator, as well as the value-add plant. In summary, the mine and concentrator will need various state and federal permits, potentially including the National Pollution Discharge Elimination System ("NPDES") permit for site-wide excess water discharge, and the US Army Corp of Engineers("USACOE") 404 permits for impacts to waters of the state and/or wetlands.

The value-add plant is proposed to be constructed in phases on an existing industrial site that is already zoned for heavy industrial and has excellent existing infrastructure, utilities and is sited near the Port of Mobile and the Intermodal Transportation facility. Similarly, the environmental permitting process for the value-add plant in accordance with Alabama environmental regulations and laws will commence in earnest, based on the results of the PEA and ongoing negotiations with the State of Alabama and local counties. Generally, it is anticipated that all permits can be secured with the proposed approach and within the BamaStar development timeline.

The BamaStar Project requires a closure bond administered by the State of Alabama. A reclamation plan and a closure cost estimate are included in the PEA.

Table 2: Permitting Matrix and Schedule

CAPEX

This section provides an overview of the Capex estimates for open pit mining of the BamaStar deposit, as well as the construction of a process plant, waste storage facilities, which includes co-disposal, and associated infrastructure. According to the PEA design, it is expected that each phase of the process plant would have an average capacity of 1.3 Mtpy for the initial phase, producing 25,000 tpy of NFG concentrate, and Phase 2 will have a similar throughput to double the production capacity to 50,000 tpy of NFG concentrate. The mine will have an estimated life of 19 years. Phase 1 mine and concentrator are scheduled to be online and producing in 2027, and Phase 2 is constructed in 2030 and producing in 2031. The mine, process plant and associated infrastructure Capex estimate are based on an Association for the Advancement of Cost Estimation ("AACE") Class 5 estimate has an accuracy range of +50%/-35%. Total initial Capex for the Phase 1 and 2 of the mine and concentrator will be US$96.9M and US$57.2M, respectively. Sustaining capital during the 19-year mine life is estimated to be US$32.7M. The Capex estimates for the value-add plant are based on an Association for the Advancement of Cost Estimation ("AACE") Class 5 estimate, with an accuracy range of -20 % to -50 % (low) and +30 % to +100 % (high). Each module of the value-add plant is estimated to cost US$269.0M.

Table 3: BamaStar CAPEX and Sustaining Capital

OPEX

Average LOM Mining OPEX is US$23.49/tonne of mill feed, and average LOM for purified micronized graphite ("PMG") is US$1,013/t of PMG No 1. and US$2,542/tonne of CSPG. The average LOM total cost of value-add product is US$2,625/tonne of product.

Economics and Sensitivities

Table 5: BamaStar PEA Economic Summary & Highlights

Description |

Unit |

LOM |

|---|---|---|

Preproduction Capex + Contingency |

US$M |

365.9 |

Subsequent Capex + Contingency |

US$M |

595.2 |

Sustaining and Closure + Contingency |

US$M |

117.3 |

Average Gross Revenue |

US$M/yr |

518.8 |

Total Gross Revenue |

US$M |

9,857.2 |

Total Operating Costs |

US$M |

2,471.7 |

Average LOM Operating Margin |

% |

72.0 |

Pretax Total Cashflow |

US$M |

5,985.8 |

Total Taxes |

US$M |

1,657.9 |

After-Tax Total Cashflow |

US$M |

4,276.9 |

Average LOM Cashflow Margin |

% |

43.7 |

Pre-tax NPV 8% |

US$M |

2,368.8 |

Pre-tax IRR |

% |

34.8 |

After-tax NPV 8% |

US$M |

1.598.3 |

After-tax IRR |

% |

27.4 |

The PEA Technical Report is prepared in accordance with the requirements set forth by Canadian NI 43-101 for the disclosure of material information and is intended to meet the requirements of a PEA level of study and disclosure as defined in the regulations and supporting reference documents. This study is preliminary in nature and includes Inferred Mineral Resources in the conceptual mine plan. Inferred Mineral Resources are considered too speculative geologically and in other technical aspects to enable them to be categorized as Mineral Reserves under the standards set forth in NI 43-101. There is no certainty that the estimates in this PEA will be realized.

Figure 8: Pretax Cashflow Summary Graphic

Figure 9: Sensitivity Analysis Summary

Commercial Strategy

South Star is developing a vertically integrated USA battery anode material strategy to supply the expanding worldwide lithium-ion battery, fuel cell, defense and industrial graphite markets. First production is planned by 2027. The combined phases of the value-add plant would produce sufficient CSPG for approximately 1 million electric vehicles ("EVs"), assuming 75kg of CSPG per vehicle and a 50% / 50% blend of synthetic and NFG CSPG. The PEA contemplates the following products:

Natural flake graphite concentrates (medium and fines);

CSPG No. 1: Coated Spherical Purified Graphite with D50 = 18 µm - Active Anode Material;

CSPG No. 2: Coated Spherical Purified Graphite with D50 = 8 µm - Active Anode Material; &

PMG No. 1: Ultra-fine Battery-grade Purified Micronized Graphite with D50 < 8 µm.

Additional products such as expandable/expanded graphites, foils, gaskets, dispersions and powders are in development and will be included in the next study phase.

South Star has a go-to-market commercial strategy to offer high-quality graphite concentrates from Santa Cruz in Brazil to a broad array of possible markets and sectors in 2024. Concurrently, technical product-development programs are continuing to advance the Company's vertically integrated midstream and downstream product suite for value-added applications various battery applications and conductivity-enhancement products applicable to all commercial primary and secondary battery chemistries and value-add materials. Pricing has been prepared with information provided by Benchmark Mineral Intelligence ("BMI"), Fastmarkets, published studies and reports, as well as confidential market studies for specific products or sectors.

Conclusions and Proposed Schedule

Based on the deposit characteristics, strategic location, encouraging potential economics, and strong performance characteristics of the products, the BamaStar Graphite Project is an important resource in the heart of one of the most important, EV, defense and stationary storage belts in the contiguous US. The US currently produces no graphite and is 100% import dependent. There is a coming imbalance between supply and demand of graphite globally, and geopolitical tensions and potential supply chain disruptions highlight the current danger for the US and its allies for a mission critical input to industrial, energy, and defense sectors, amongst others.

BamaStar has significant tangible advantages including:

Location in the contiguous US with excellent access to existing infrastructure and logistics, which results in a much lower capital intensity, when compared to viable alternatives

Start of mining operations in oxide mill feed, which allows for less expensive initial CAPEX and OPEX when compared to hard rock deposits during the critical payback period.

Installations on private mining claims and private property, which allows for licensing and permitting to be secured in an estimated 18-24 months, based on preliminary consultations with State of Alabama officials and local consultants.

When combined with production from Santa Cruz Graphite Mine in Brazil, which is ramping up Phase 1 commercial production, South Star is positioned to be one of the first movers in vertically integrated graphite production in the Americas with scalable assets in Tier 1 jurisdictions and an experienced management of mine builders and operators. First concentrate sales are planned for October 2024 at Santa Cruz and integrated, value-add production in the US is planned for 2027.

The proposed value-add plant built on a vacant, zoned Heavy Industrial I/2 property near the Port of Mobile with existing utilities, logistics and other infrastructures available. This allows for much lower capital intensity as existing infrastructure, logistics, and supply chains are utilized and require less investment.

Ability to scale in a phased, modular approach to control risks and deal effectively with market conditions, financing requirements, permitting and licensing schedules and commercial realities. Alternatively, it can be built in one phase in about two years, if the urgent production and provenance of supply play an increasingly critical role in global supply chains and production is required quickly.

The results of the PEA demonstrate that BamaStar is potentially financially viable with encouraging economics, products with strong performance characteristics, relatively modest capital intensities and located in a strategic region of contiguous US. With a positive funding decision by the South Star Board of Directors, a NI 43-101 FS is estimated to be completed in approximately 18 months from the mobilization of drill rigs.

Qualified Persons and Full Report

Lycopodium Minerals Canada Ltd. ("Lycopodium"), in conjunction with Mercator Geological Services Ltd. ("Mercator"), AGP Mining Consultants Inc. ("AGP"), MetPro Management Inc. ("MetPro"), Global Resource Engineering ("GRE"), and Dorfner Anzaplan GmbH ("ANZAPLAN") have prepared the NI 43-101 PEA Technical Report on the BamaStar Graphite Project. For readers to fully understand the information in this press release, they should read the Technical Report in its entirety when it is available on SEDAR+, including all qualifications, assumptions, and exclusions that relate to the information to be set out in the Technical Report, which qualifies the technical information contained in the Technical Report. The Technical Report will be filed on SEDAR + and Company's website within 45 days of this press release and is intended to be read as a whole, and sections should not be read or relied upon out of context.

The technical information contained in this news release has been reviewed and approved by the following QPs

Overall Study Author: Jacob Makil, P.Eng. Study Manager, Lycopodium

Mineral Resources: Matthew Harrington, P.Geo., Senior Resource Geologist, Mercator

Mining Methods: Gordon Zurowski, Principal Mine Engineer, AGP Mining Consultants Inc.

Mineral Processing (Graphite Concentrate): Oliver Peters of MetPro and Sunil Koppalkar, P.Eng of Lycopodium on Recovery Methods

Capital and Operational Cost Estimation (Mine and Graphite Concentrate): Gordon Zurowski, Principal Mine Engineer, AGP Mining Consultants Inc and Jacob Makil, P.Eng, Study Manager, Lycopodium

Recovery and Processing (Value-Add Plant & HF purification): Derick R de Wit of ANZAPLAN

Capital and Operational Cost Estimation (Value-Add Plant): Derick R de Wit of ANZAPLAN

Water Management / Environmental Licensing and Permitting: J. Larry Breckenridge, P.E.

Pre-tax Economics Analyses: Preetham Nayak, P.Eng., Lycopodium

By virtue of education and relevant experience, the aforementioned are independent "Qualified Persons" for the purpose of NI 43-101. The market studies and tax model were developed by South Star personnel and consultants. Downstream sample transformation and electrochemical tests programs for value-add plant were performed by an independent battery laboratory service provider in North America and overseen by South Star personnel and their technical consultants.

1 - The PEA Technical Report is prepared in accordance with the requirements set forth by Canadian NI 43-101 for the disclosure of material information and is intended to meet the requirements of a PEA level of study and disclosure as defined in the regulations and supporting reference documents. This study is preliminary in nature and includes Inferred Mineral Resources in the conceptual mine plan. Inferred Mineral Resources are considered too speculative geologically and in other technical aspects to enable them to be categorized as Mineral Reserves under the standards set forth in NI 43-101. There is no certainty that the estimates in this PEA will be realized.

NON-IFRS AND OTHER FINANCIAL MEASURES

This document refers to Average LOM OPEX per tonne. This is a non-IFRS financial measure. The Company believes that this measure provides additional insight, but this measure is not a standardized financial measure prescribed under International Financial Reporting Standards ("IFRS") and therefore should not be confused with, or used as an alternative for, performance measures calculated according to IFRS. Furthermore, this measure should not be compared with similarly titled measures provided or used by other issuers. The non-IFRS financial measure used in this document are relatively common to the mining industry.

# # #

About South Star Battery Metals Corp.

South Star is a Canadian battery-metals project developer focused on the selective acquisition and development of near-term production projects in the Americas. South Star's Santa Cruz Graphite Project, located in Southern Bahia, Brazil is the first of a series of industrial- and battery-metals projects that will be put into production. Brazil is the second-largest graphite-producing region in the world with more than 80 years of continuous mining. Santa Cruz has at-surface mineralization in friable materials, and successful large-scale pilot-plant testing (> 30 tonnes) has been completed. The results of the testing show that approximately 65% of graphite concentrate is +80 mesh with good recoveries and 95%-99% graphitic carbon (Cg). With excellent infrastructure and logistics, South Star Phase 1 is ramping up commercial production with first sales expected to be delivered in October 2024. Santa Cruz Phase 1 commercial production has a nameplate capacity of 12,000 tpy and is the first new graphite production in the Americas since 1996. Phase 2 production (25,000 tpy) is partially funded and planned for 2026, while Phase 3 (50,000 tpy) is scheduled for 2028.

South Star's second project in the development pipeline is strategically located in Alabama, U.S.A. in the center of a developing electric-vehicle, aerospace, and defense hub in the southeastern United States. The BamaStar Project includes a historic mine active during the First and Second World Wars. A NI 43-101 Preliminary Economic Assessment will be filed on SEDAR+ within 45 days of this Press Release. Trenching, Phase 1 drilling, sampling, analysis, and preliminary metallurgical testing have been completed. The testing included a traditional crush/grind/flotation concentration circuit that achieved grades of approximately 94-99% Cg with approximately 90% recoveries. The vertically integrated production facilities include a mine and industrial concentrator in Coosa County, AL and a downstream value-add plant in Mobile, AL, which will be upgrading natural flake graphite concentrates from both Santa Cruz and BamaStar mines. South Star is executing on its plan to create a multi-asset, diversified battery-metals company with near-term operations in strategic jurisdictions. South Star trades on the TSX Venture Exchange under the symbol STS, and on the OTCQB under the symbol STSBF.

South Star is committed to a corporate culture, project execution plan and safe operations that embrace the highest standards of ESG principles, based on transparency, stakeholder engagement, ongoing education, and stewardship. To learn more, please visit the Company website at http://www.southstarbatterymetals.com .

This news release has been reviewed and approved for South Star by Richard Pearce, P.E., a "Qualified Person" under National Instrument 43-101 and President and CEO of South Star Battery Metals Corp.

On behalf of the South Star Board of Directors,

MR. RICHARD L. PEARCE,

President & Chief Executive Officer

For additional information, please contact:

South Star Investor Relations

Email: invest@southstarbatterymetals.com

Phone: +1 (604) 706-0212

Website: www.southstarbatterymetals.com

Twitter: https://twitter.com/southstarbm

Facebook: https://www.facebook.com/southstarbatterymetals

LinkedIn: https://www.linkedin.com/company/southstarbatterymetals/

YouTube: South Star Battery Metals - YouTube

CAUTIONARY STATEMENT

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this press release.

Forward-Looking Information

This press release contains "forward-looking statements" within the meaning of applicable securities legislation. Forward-looking statements relate to information that is based on assumptions of management, forecasts of future results, and estimates of amounts not yet determinable. Any statements that express predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance are not statements of historical fact and may be "forward-looking statements". Forward-looking statements in this press release include, but are not limited to statements regarding moving Santa Cruz into production and scaling operations; the company's plans for the development and construction of a mine and concentrator plant for the BamaStar Project; the financial estimates provided in the PEA, including net present value and internal rates of return; statements relating to the permitting process; the proposed design and operating parameters of the mining plan for the BamaStar Project provided in the PEA, including projected capital, operating costs, annual production, projected metallurgical recoveries, life of mine and projected timelines; future demand for graphite; and the Company's other plans and expectations.

Forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ from those reflected in the forward-looking statements, including, without limitation risks related to: failure to obtain adequate financing on a timely basis and on acceptable terms; the outcome of legal proceedings; political and regulatory risks associated with mining and exploration; the maintenance of stock exchange listings; environmental regulation and liability; the potential for delays in exploration or development activities or the completion of feasibility studies; the uncertainty of profitability; risks and uncertainties relating to the interpretation of drill results, the geology, grade and continuity of mineral deposits; inherent uncertainty of production and cost estimates and the potential for unexpected costs and expenses; the Company may not obtain all necessary governmental permits; results of prefeasibility and feasibility studies, and the possibility that future exploration, development or mining results will not be consistent with the Company's expectations; risks related to commodity price fluctuations; and other risks and uncertainties related to the Company's prospects, properties and business detailed elsewhere in the Company's disclosure record. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in forward-looking statements. Assumptions used by the Company to develop forward-looking statements include the assumptions that (i) the BamaStar Project will ultimately obtain all required environmental and other permits and licenses without undue delay, (ii) any feasibility studies prepared for the development of the BamaStar Project will be positive, (iii) the Company's estimates of mineral resources will not change, and the Company will be successful in converting mineral resources to mineral reserves, (iv) the Company will be able to establish the commercial feasibility of the BamaStar Project, and (v) the Company will be able to secure the financing required to develop the BamaStar Project.

Investors are cautioned against attributing undue certainty to forward-looking statements. These forward-looking statements are made as of the date hereof and the Company does not assume any obligation to update or revise them to reflect new events or circumstances except as required by applicable laws. Actual events or results could differ materially from the Company's expectations or projections.

SOURCE: South Star Battery Metals Corp.

View the original press release on accesswire.com