LUCK, Wis. - Oct. 24, 2024 - PRLog -- Urethane Liners 101

Urethane liners are more durable and longer lasting than traditional steel liners. Their inherent flexibility helps absorb impact, reducing wear and minimizing the risk of cracking or breaking. In addition to their durability, urethane liners also offer a quieter operation by reducing noise levels in cement blending processes. This not only protects the equipment but also creates a safer and more pleasant working environment for employees. Some urethane solutions are customizable to fit various equipment types, ensuring seamless integration and optimal protection.

Tailored Solutions for Concrete Equipment

Urethane wear parts are designed to address the specific challenges faced by concrete plants and equipment. Whether you're operating a batch plant, continuous mixer, or any other type of cement blending system, these wear parts provide protection in high-wear areas, helping to reduce the need for frequent repairs. Custom-fabricated to match your equipment specifications, wear parts deliver maximum performance and durability, even in the most demanding applications.

In addition to their protective qualities, urethane liners and wear parts promote better material flow. By preventing material build-up and promoting smooth movement, urethane components can improve efficiency and reduce energy consumption in your concrete blending operations. The non-stick properties of urethane help prevent cement from adhering to surfaces, ensuring smoother operation and reducing the frequency of cleaning.

The Importance of Regular Maintenance

While urethane liners and wear parts significantly improve the durability of cement blending equipment, regular maintenance is still essential to ensure optimal performance. Routine inspections should be conducted to check for signs of wear, such as thinning or damage to the liners. Replacing worn parts promptly will prevent further damage to the equipment and minimize downtime and by establishing a consistent maintenance schedule, you can identify and address issues before they escalate into costly repairs or replacements.

Best Practices for Cleaning Cement Blending Equipment

Cleaning cement blending equipment is vital to preventing build-up and maintaining efficiency. Regularly removing accumulated cement, sand, and other materials from hoppers, chutes, and mixers ensures smooth operation and reduces wear on urethane liners and wear parts. High-pressure water or air can be used to remove debris, but care should be taken to avoid damaging the liners.

For stubborn build-up, using specialized cleaning tools designed for concrete equipment can help remove hardened material without harming the urethane components. It's essential to clean hard-to-reach areas, such as corners and seams, to prevent the build-up of material that could compromise equipment performance over time. Additionally, using cleaning agents that are safe for urethane materials will ensure that your liners and wear parts remain in good condition after each cleaning cycle.

Not All Urethane Liners Are the Same

In the concrete production industry, equipment endures constant exposure to abrasive materials such as sand, gravel, and cement, which can lead to premature wear and tear. Yet you can count on high quality reliable liners to extend the lifespan of your equipment, reduce maintenance costs, and improve overall operational efficiency.

However, keep in mind not all urethane liners and wear parts will perform as promised and why it is essential to choose a high-quality manufacturer of urethane liners such as Durex Products to ensure maximum durability and protection against abrasive materials.

About Durex Products

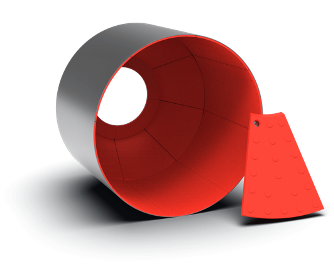

Durex's urethane concrete liners and wear parts are specifically designed for concrete plants and equipment to withstand the harsh conditions of concrete production. Durex liners are particularly effective in protecting areas prone to high impact and wear, such as hoppers, chutes, and mixing drums and are customizable to fit various equipment types, ensuring seamless integration and optimal protection.

In conclusion, investing in Durex Products' urethane concrete liners and wear parts is a smart choice for any concrete plant or equipment operator looking to improve durability and performance. With proper maintenance and cleaning practices, these urethane solutions are designed to extend your equipment's lifespan, lower operational costs, and ensure peak production efficiency. To learn more about our products visit: https://durexproducts.com

Contact

Nanette Gregory

***@nsgconsultinginc.com

Photos: (Click photo to enlarge)

Source: Durex Products

Read Full Story - Enhance Your Concrete Plant Equipment Durability with Urethane Liners, Wear Parts and Regular Maintenance | More news from this source

Press release distribution by PRLog

Enhance Your Concrete Plant Equipment Durability with Urethane Liners, Wear Parts and Regular Maintenance

October 24, 2024 at 20:05 PM EDT